Stretch Wrap Turntable (High Profile)

Stretch Wrap Turntable (High Profile)

Stretch Wrap Turntable (High Profile)

AZ-30H

Prices

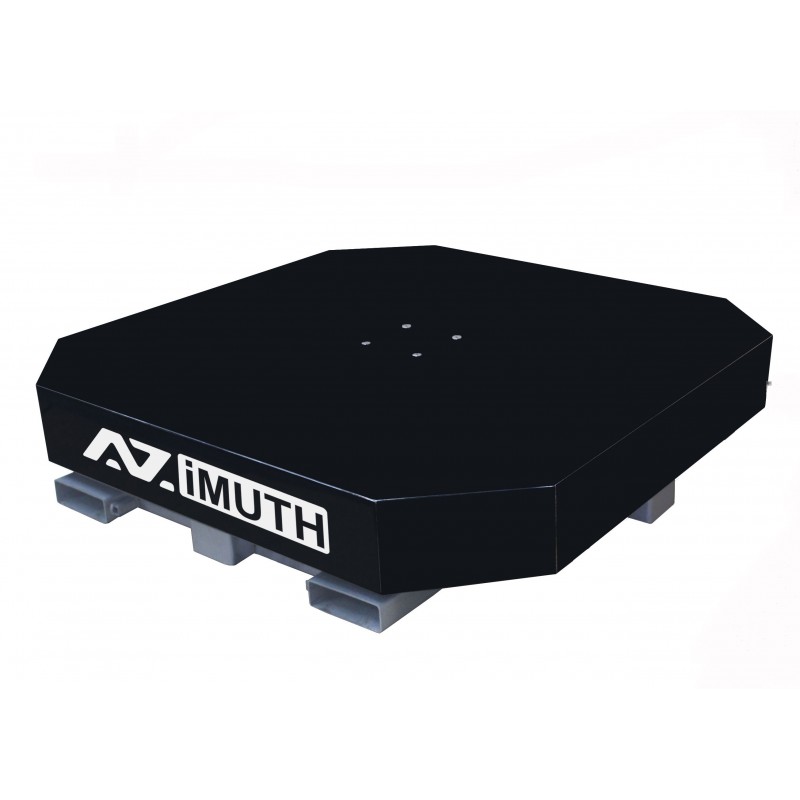

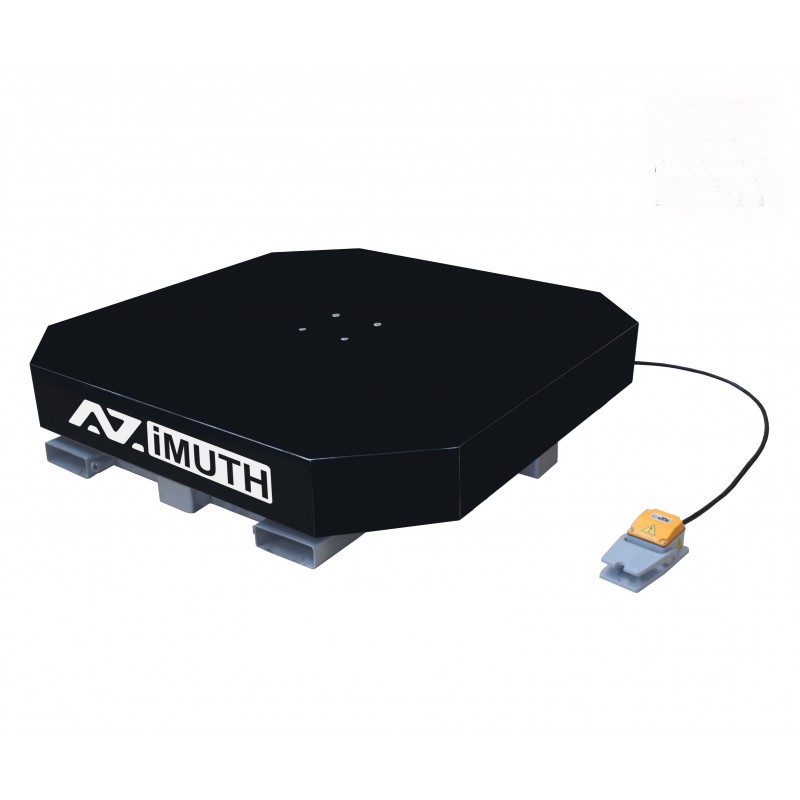

48"x48" TURNTABLE

Lead time is up to 1 business week

SCALE NOT INCLUDE

Lead time is up to 1 business week

SCALE NOT INCLUDE

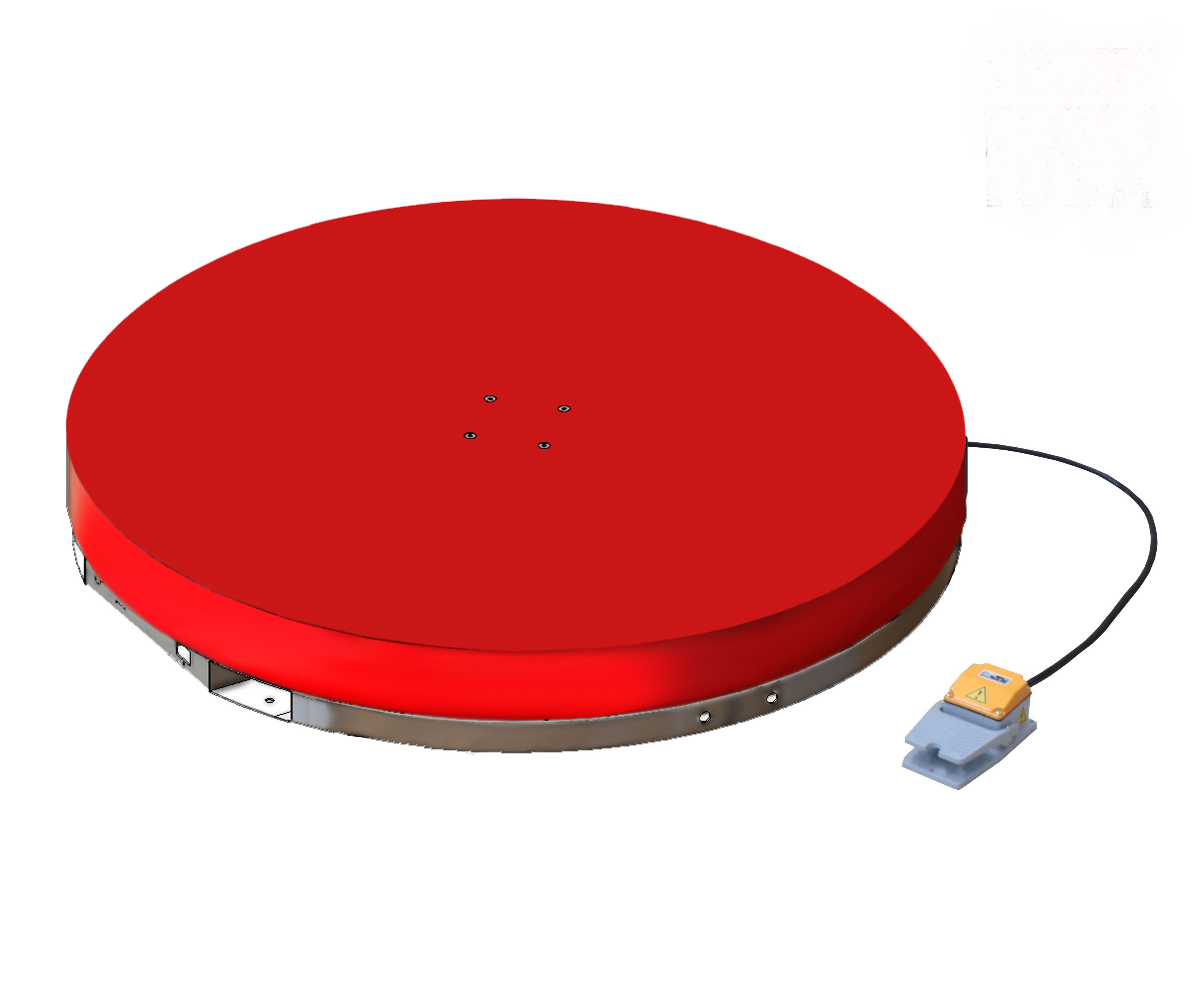

HIGH PROFILE TURNTABLE AZ-303R

HIGH PROFILE TURNTABLE AZ-303RTURNTABLE IS ROUND AND RED

SCALE NOT INCLUDE

Lead time is up to 2 business days

60"x60" TURNTABLE

Lead time is up to 1 business week

SCALE NOT INCLUDE

Lead time is up to 1 business week

SCALE NOT INCLUDE

AZ-Link 2.4 Wireless Control Film Dispenser

AZ-Link 2.4 Wireless Control Film DispenserFILM IS NOT INCLUDE

SCALE Option

Can to be used with Receipt Printer ONLY (Printer not include)

CANNOT TO BE PURCHASED SEPARATELY. Installation only in production

| SKU | MAX. SKID SIZE | DIMENSIONS | LOAD CAPACITY | PRICE | SALE | TO CART | |

|---|---|---|---|---|---|---|---|

| AZ-303 | | 80 x 80" | 48" x 48" | 4000 LBS | $3,040 | $3,040.00 |

| SKU | MAX. SKID SIZE | DIMENSIONS | LOAD CAPACITY | PRICE | SALE | TO CART | |

|---|---|---|---|---|---|---|---|

| AZ-303R | | 85" x 85" | 59" DIA | 5000 LBS | $3,350 | $3,350.00 |

| SKU | MAX. SKID SIZE | DIMENSIONS | LOAD CAPACITY | PRICE | SALE | TO CART | |

|---|---|---|---|---|---|---|---|

| AZ-304 | | 96 x 96" | 60" x 60" | 5000 LBS | $3,840 | $3,840.00 |

| SKU | DISPENSER CAPACITY | CORE | CONTROL | PRICE | RANGE | TO CART | |

|---|---|---|---|---|---|---|---|

| AZ-LINK-D | | 12", 15", 18", 20" rolls | 1.5" - 2" - 3" | MANUAL | $395 | 30 ft |

| SKU | PRECISION | INDICATOR | PRICE | TO CART | |

|---|---|---|---|---|---|

| AZ-TSCALE | | 1 LBS | LCD | $1,100.00 |

AZIMUTH High-Profile Stretch Wrap Turntable Machine – The Ultimate Turntable Pallet Wrapper

The AZIMUTH High-Profile Stretch Wrap Turntable Machine provides full control over the wrapping cycle, making it the perfect turntable pallet wrapper to boost productivity in warehouses and distribution centers. Built for durability, this manual pallet wrapping solution features a chain-driven steel turntable with an impressive 4,000 to 5,000 lbs load capacity, ensuring reliable and secure wrapping for heavy and oversized pallets.

Why Choose the AZIMUTH High-Profile Turntable Pallet Wrapper?

- Efficient Wrapping Performance – Handles 12 to 15 loads per hour with an adjustable 12 RPM speed.

- Heavy-Duty Load Capacity – Supports up to 4,000 or 5,000 lbs, perfect for industrial use.

- Oversized Pallet Compatibility – Wraps skids up to 80"x80" or 96"x96", accommodating larger loads.

- Reliable Chain-Driven Turntable – Ensures smooth and consistent rotation for secure wrapping.

- User-Friendly Foot Pedal Control – Semi-automatic operation with adjustable rotation speed.

- Optional AZ-Link 2.4 Remote Control Stretch Film Dispenser – Upgrade your wrapping process with wireless remote functionality. The AZ-Link 2.4 remote-controlled stretch film dispenser enables operators to control both film dispensing and turntable operation, minimizing manual labor, enhancing efficiency, and maximizing productivity. This advanced feature is perfect for warehouses aiming to streamline operations and reduce downtime.

- Powerful Motor – Equipped with a 110V, 3/4HP motor for continuous high-performance operation.

- Optional Built-In Scale – Weigh and wrap pallets in one step, reducing handling time and improving efficiency for streamlined warehouse operations.

- Forklift-Accessible Design – The 10" tall turntable is easily accessible by forklift from the front and rear, allowing for quick and effortless loading.

- Easy Installation & Low Maintenance – Simple to set up, operate, and requires minimal maintenance.

Boost efficiency and streamline your pallet wrapping process with the AZIMUTH High-Profile Stretch Wrap Turntable Machine – a rugged, high-capacity, and easy-to-use solution for any warehouse!

2 Years Warranty. Made in USA.

| AZ-303R Turntable | AZ-303 Turntable | AZ-304 Turntable | |

|---|---|---|---|

| Load Capacity | up to 4 000 LBS | up to 4 000 LBS | up to 5 000 LBS |

| Turntable Speed Adjustable | from 0 to 12 RPM | ||

| Stretch Film Tension | Manual | ||

| Production Rate | 12-15 Loads Per Hour | ||

| Turntable | 59" DIA, Diamond Plate Top, High Profile | 48" x 48", Diamond Plate Top, High Profile | 60" x 60", Diamond Plate Top, High Profile |

| Power Consumption | 110V, 10A | ||

| Machine Length | 59" | 48" | 60" |

| Machine Height | 10" | ||

| Package Size | 60" x 60" x 16" | 48" x 48" x 16" | 60" x 60" x 16" |

| Net Weight | 550 lbs | 450 lbs | 570 lbs |

| Gross Weight | 600 lbs | 420 lbs | 600 lbs |

| Max Skid Size | 80x80" or 96x96" |

| Wrap Height | No Limit |

| Load Capacity | up to 4000 or 5000 LBS |

| Turntable Speed | from 0 to 12 RPM |

| Production Rate | Up to 12 - 15 Load per Hour |

| Turntable | 48" x 48" or 60" x 60", Diamond Plate Top, High Profile |

| Power Consumption | 115V, 10A |

| Machine Length | 48" or 60" |

| Machine Height | 10" |

| Type | Manual |

| Permitted Ambient Conditions | Indoor Usage only. |

| Temperature | between 41°F and 113°F. To work below 41°F need to be FREEZER Version. |

| Atmospheric Conditions | not greater than 50% at a temperature of 104°F and 90% at a temperature not over 68°F (without condensation) |

| Loading Option | Forklift only |

| Material | Steel |

| Package Size | 60" x 60" x 15" |

| Gross Weight | 570 lbs |

| Net Weight | 600 lbs |

| Color | Grey/Black (color may vary) |

| Liftgate Delivery | NO |

| Warranty | 2 years |

| Positioning | May be mounting to the floor if needed |

| Review Count | 25 |

| Rating Value | 4.9 |