AZIMUTH 3012 Low Profile Pallet Wrapper (65"x92") with PRESS

AZIMUTH 3012 Low Profile Pallet Wrapper (65"x92") with PRESS

AZIMUTH 3012 Low Profile Pallet Wrapper (65"x92") with PRESS

AZIMUTH 3012-PRESS Universal Pallet Wrapper

The AZIMUTH 3012 is a PRESS low-profile stretch wrapper with a 65-inch diameter turntable and 92-inch wrap height and 4,000 lbs load capacity.

AZIMUTH-3012-PRESS Features:

- The maximum amount of adjustment in the base.

- Max Pallet size - 52 x 52 x 92"

- Load Capacity - up to 4 000 LBS

- Adjust from 20% to 150% stretch Chain drive. Compatible with 3" core stretch film rolls (up to 20" height)

- Digital control panel. Selection of wrapping parameters and save it in the program memory.

- Convenient photo eye - allow operator to walk away.

- 115 volt, 15A

Prices

Lead Time is Up to 2 business week

Custom made option

Can to be used with Receipt Printer ONLY. (Printer not include)

CANNOT TO BE PURCHASED SEPARATELY. Installation only in production

| SKU | MAX. SKID SIZE | LOAD CAPACITY | SALE | TO CART | |

|---|---|---|---|---|---|

| AZ-3012-PRESS | 52 x 52 x 92" | 4000 LBS | $10,080.00 |

| SKU | LOAD CAPACITY | PRECISION | INDICATOR | SALE | TO CART | |

|---|---|---|---|---|---|---|

| AZ-CSCALE | | 4000 LBS | 1 LBS | LED | $1,450.00 |

| SKU | FOR PALLET JACK | DIMENSIONS | SHPG. WT. | SALE | TO CART | |

|---|---|---|---|---|---|---|

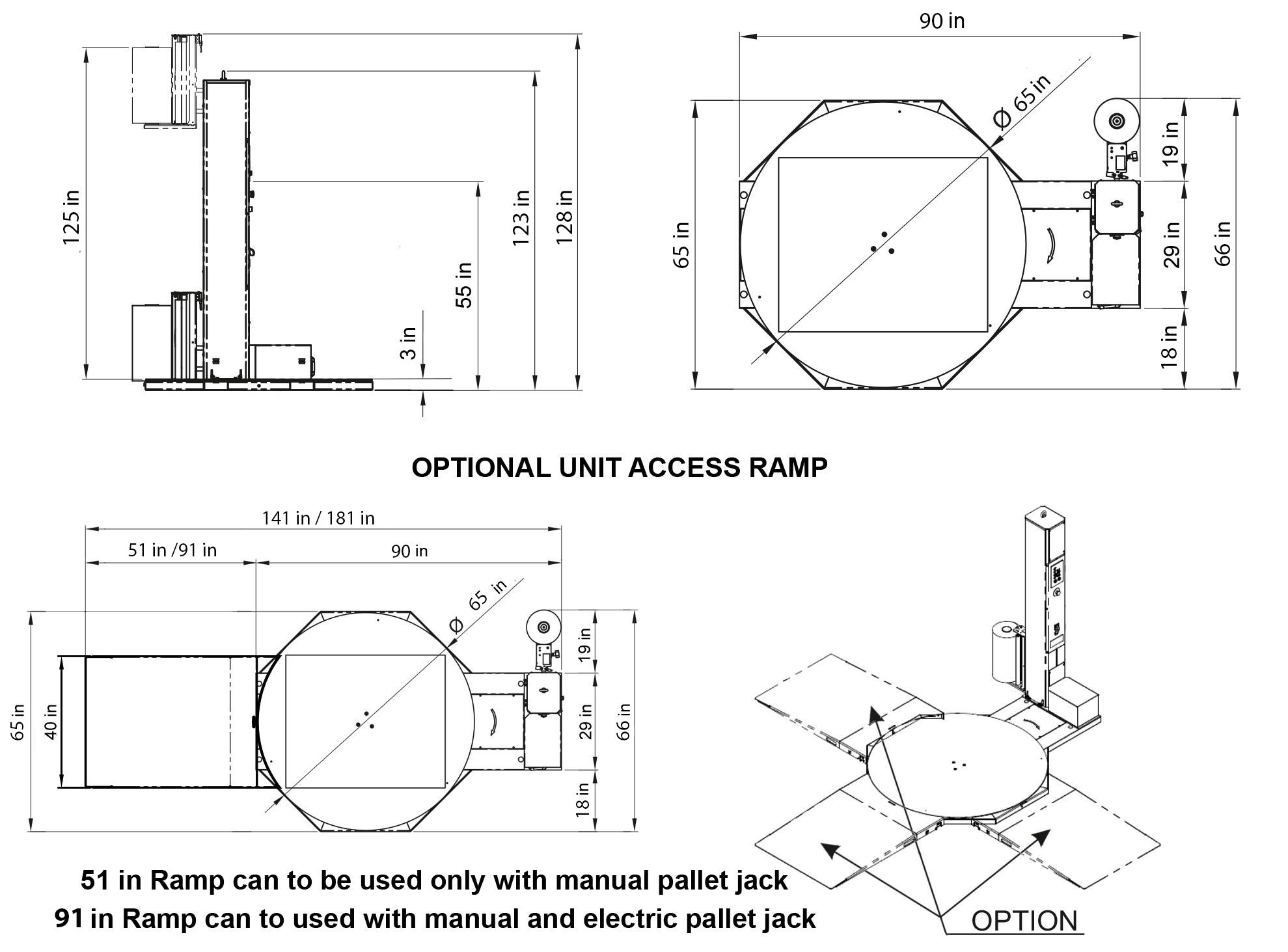

| AZ-R16 | | MANUAL ONLY | 40 x 58 x 3'' | 250 LBS | $800.00 |

AZIMUTH 3012 PRESS Low Profile Stretch Wrappers

The AZIMUTH-3012 PRESS Pallet Wrapping Machine - Best Price and Best Functionality

- The maximum amount of adjustment in the base.

- It's very easy to install simple to operate and virtually zero maintenance.

- Can be moved by Forklift at the Front and at the Rear side of Turntable.

- Digital control panel. Selection of 10 wrapping parameters and save it in the 99 programs.

- Max SKID Size: 52"x52"x92"

- Wrap Height: UP to 92"

- Load Capacity: up to 4 000 LBS

- Turntable Speed Adjustable: from 0 to 12 RPM

- Stretch Film Tension: manual, 20% - 160%

- Production Rate: 10-20 Loads Per Hour

- Turntable: 65" Round Smooth Top, Low profile, Chain Drive

- Use with Machine Stretch Wrap 3 in core Stretch Wrap rolls. Up to 20 in height

- Convenient photo eye - allow operator to walk away. Standard Photo Eye Sensor - reads loads 25 in or taller. May not work with red, blue and black surfaces (use Manual Mode or Mode with Present Height).

- Permitted Ambient Conditions: Indoor Usage only.

- Temperature: 41°F and above. To work below this temperature need to be FREEZER Version.

- Atmospheric Conditions: not greater than 50% at a temperature of 104°F and 90% at a temperature not over 68°F (without condensation)

- Color may very

- NO liftgate delivery

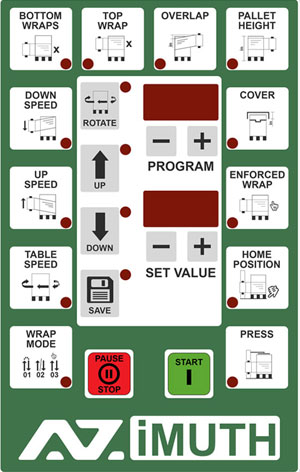

Control Panel Functions

- Separate numbers of Enforced Wraps at bottom/top SKID.

- Adjusting the rotation speed of the Pallet Wrapper Turntable

- Customization SKID wrapping height (if necessary)

- Soft Start and Soft Stop at home position of Pallet Wrapper Turntable

- Setting the carret up/down moving speed

- 99 Customized Wrapping Programs Profiles memory

- Protection from change Wrapping Parameters

- Sound Signals at Start and End of Wrapping cycles

- Setting the upper Overlap the top of the cargo

- Function to wrap SKID using plastic or corrugated Top Cover

- Emergency Stop Button

- Active Compression Protection System

- Manual Wrapping Mode

Pallet Wrapper Dimensions

Enhanced Load Stability and Product Protection:

- Securely Bundled Pallets: Pallet wrappers create a tight, consistent film layer around your palletized goods, preventing them from shifting or toppling during transportation or storage. This minimizes the risk of product damage, ensuring your products reach their destination in pristine condition.

- Reduced Damage Costs: By preventing product damage, pallet wrappers can significantly reduce associated costs. This includes minimizing product replacements, returns, and potential customer dissatisfaction.

A pallet wrapper with a press option is designed to provide extra stability for light or unstable loads during the wrapping process, preventing them from shifting or falling off the pallet. This feature is especially useful when wrapping irregularly shaped items, fragile products, or lightweight packages that may not stay securely in place on their own.

Here’s how the press option typically works in these machines:

- Press Mechanism: The press system applies a controlled amount of force on the load, pushing it slightly downwards or compressing it against the pallet. This helps to secure the items firmly in place before the wrapping process begins.

- Stabilization: As the machine wraps the load, the press system ensures that the items stay stable and do not shift, even if the load is unstable or top-heavy.

- Better Load Containment: By stabilizing the load during wrapping, the machine ensures that the stretch film adheres tightly to the items, reducing the risk of shifting or toppling during transportation or storage.

- Adjustable Pressure: Some pallet wrappers with this feature allow for adjustable pressure, so you can fine-tune the force applied based on the type of load being wrapped.

Benefits:

- Improved Stability: Ideal for light or unstable loads, reducing the risk of damage or accidents.

- Efficiency:The press system reduces the need for manual intervention and ensures consistent results.

- Secure Packaging: Ensures a tightly wrapped load, which can help prevent damage during handling, storage, and transportation.

These types of machines are often used in industries like logistics, manufacturing, and warehousing, where loads need to be wrapped securely before shipment or storage.

| Max Skid Size | 52x52x92" |

| Wrap Height | Up ro 92" |

| Load Capacity | Up to 4 000 LBS |

| Turntable Speed | from 0 to 12 RPM |

| Stretch film Tension | Manual, 20% - 160% |

| Production Rate | Up to 20 Loads Per Hour |

| Turntable | 65 in Diameter, Round Smooth Top, Low profile, Chain Drive |

| Power Consumption | 115V, 15A |

| Machine Length | 90 in |

| Machine Height | 123 in |

| Type | Semi-Automatic |

| Stretch Wrap | 3 in core Stretch Wrap rolls. Up to 20 in height. Up to 35 lbs |

| Height Sensing | Standard Photo Eye Sensor - reads loads 25 in or taller. May not work with red, blue and black surfaces (use Manual Mode or Mode with Present Height). |

| Permitted Ambient Conditions | Indoor Usage only. |

| Temperature | between 41°F and 113°F. To work below 41°F need to be FREEZER Version. |

| Atmospheric Conditions | not greater than 50% at a temperature of 104°F and 90% at a temperature not over 68°F (without condensation) |

| Loading Option | Forklift or Pallet Jack (need Ramp Option) |

| Material | Steel |

| Package Size | 130 x 68 x 20" |

| Gross Weight | 1 100 lbs |

| Net Weight | 1000 lbs |

| Color | Grey/Green (color may vary) |

| Liftgate Delivery | NO |

| Warranty | 2 years |

| Positioning | May be mounting to the floor if needed |

| Review Count | 4 |

| Rating Value | 5 |