AZIMUTH 3011 Low Profile Stretch Wrappers

The AZIMUTH-3011 Pallet Wrapping Machine - Best Price and Best Functionality

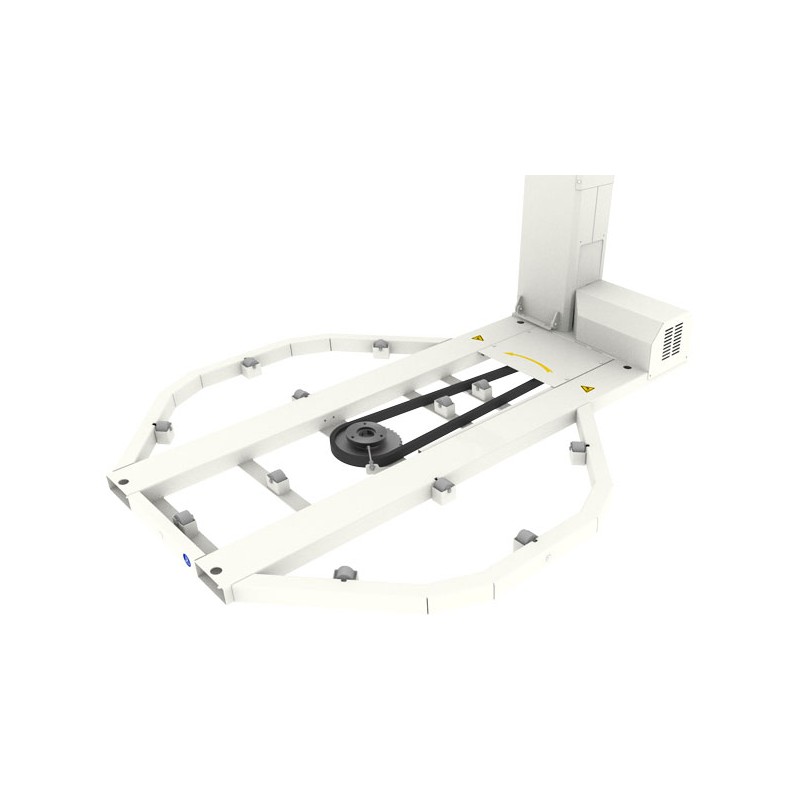

- The maximum amount of adjustment in the base.

- It's very easy to install simple to operate and virtually zero maintenance.

- Can be moved by Forklift at the Front and at the Rear side of Turntable.

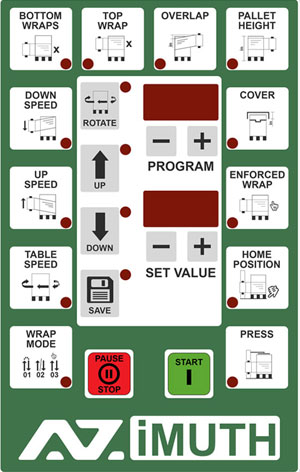

- Digital control panel. Selection of 10 wrapping parameters and save it in the 99 programs.

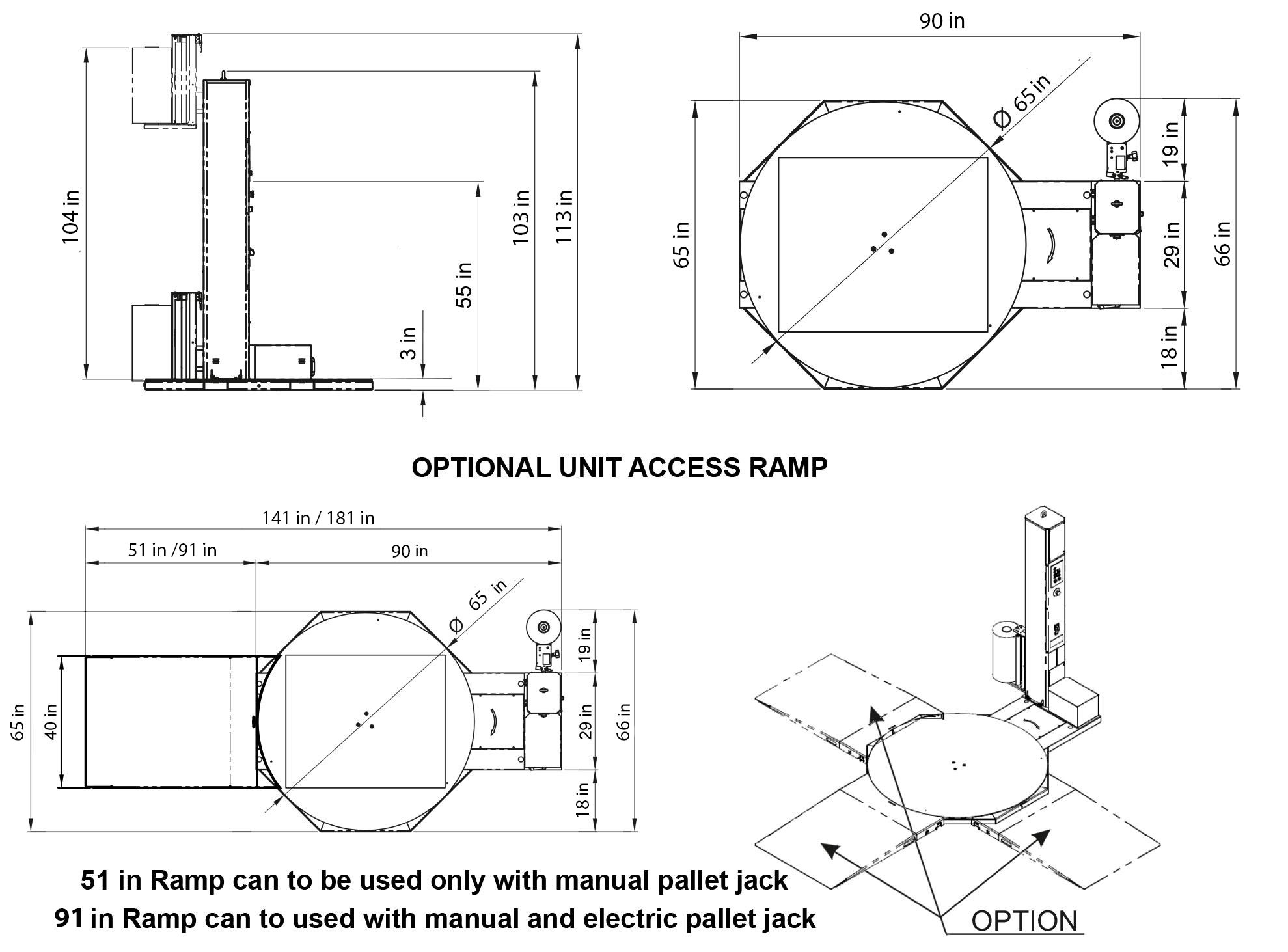

- Max SKID Size: 52"x52"x104"

- Wrap Height: UP to 104"

- Load Capacity: up to 4 000 LBS

- Turntable Speed Adjustable: from 0 to 12 RPM

- Stretch Film Tension: manual, 20% - 160%

- Production Rate: 10-20 Loads Per Hour

- Turntable: 65" Round Smooth Top, Low profile, Chain Drive

- Use with Machine Stretch Wrap 3 in core Stretch Wrap rolls. Up to 20 in height

- Convenient photo eye - allow operator to walk away. Standard Photo Eye Sensor - reads loads 25 in or taller. May not work with red, blue and black surfaces (use Manual Mode or Mode with Present Height).

- Permitted Ambient Conditions: Indoor Usage only.

- Temperature: 41°F and above. To work below this temperature need to be FREEZER Version.

- Atmospheric Conditions: not greater than 50% at a temperature of 104°F and 90% at a temperature not over 68°F (without condensation)

- Color may very

- NO liftgate delivery

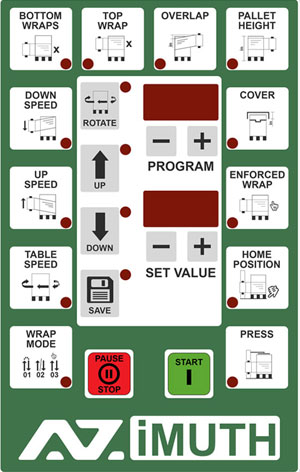

Control Panel Functions

- Separate numbers of Enforced Wraps at bottom/top SKID.

- Adjusting the rotation speed of the Pallet Wrapper Turntable

- Customization SKID wrapping height (if necessary)

- Soft Start and Soft Stop at home position of Pallet Wrapper Turntable

- Setting the carret up/down moving speed

- 99 Customized Wrapping Programs Profiles memory

- Protection from change Wrapping Parameters

- Sound Signals at Start and End of Wrapping cycles

- Setting the upper Overlap the top of the cargo

- Function to wrap SKID using plastic or corrugated Top Cover

- Emergency Stop Button

- Active Compression Protection System

- Manual Wrapping Mode

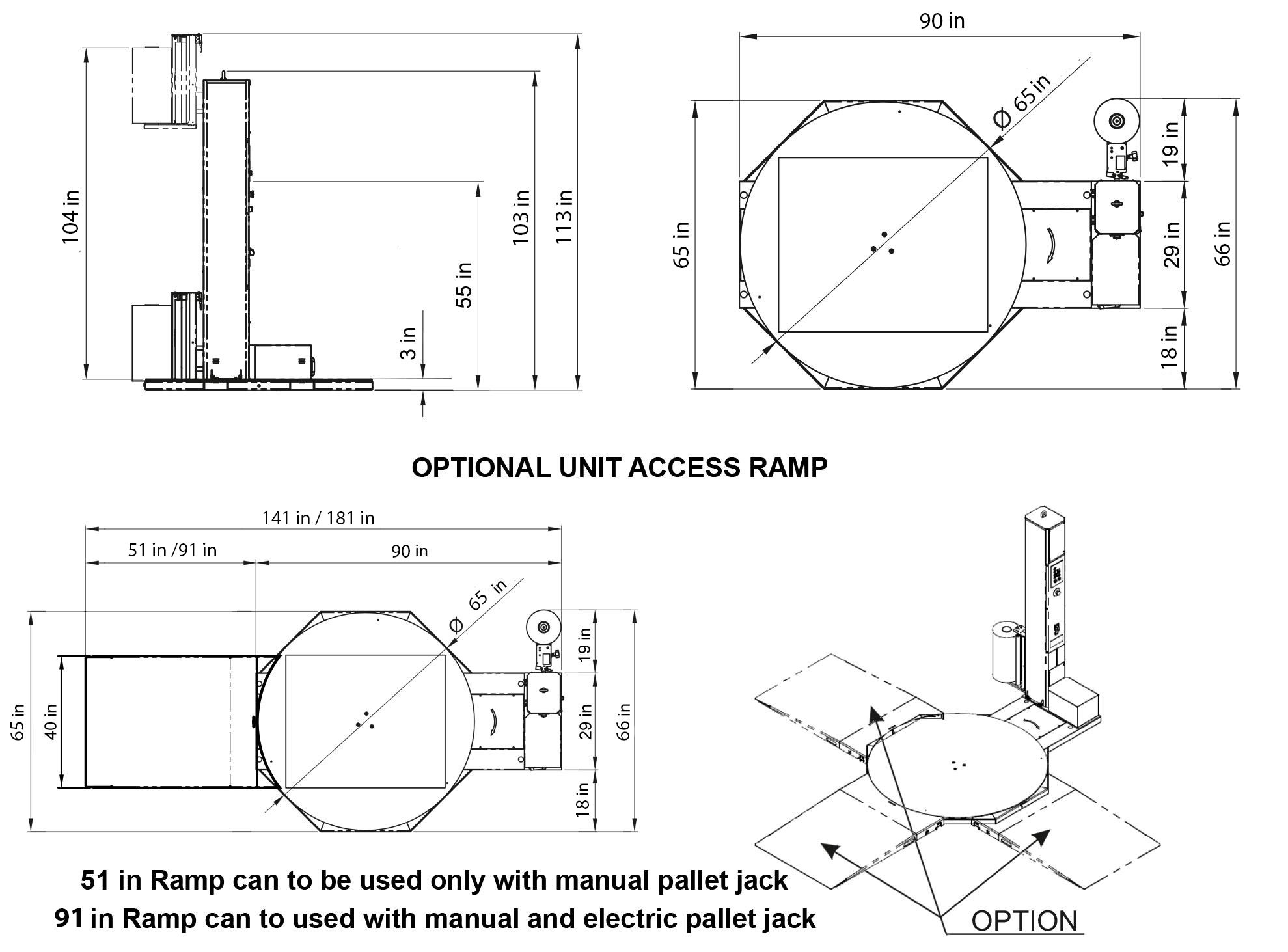

Pallet Wrapper Dimensions

Unveiling the Advantages of Stretch Wrappers in Packaging Operations

In the realm of packaging and logistics, stretch wrappers emerge as pivotal tools that revolutionize efficiency, productivity, and product protection. This article delves into the myriad benefits offered by stretch wrappers and their indispensable role in modern packaging operations.

Introduction

Stretch wrappers stand as the cornerstone of modern packaging solutions, offering a plethora of advantages that elevate efficiency and safeguard goods throughout the supply chain. This article explores the transformative impact of stretch wrappers and their unmatched benefits in packaging operations.

Efficiency Redefined

Stretch wrappers redefine efficiency by automating the wrapping process, significantly reducing the time and labor required compared to manual methods. Their swift and consistent wrapping of multiple pallets optimizes workflow, enhancing productivity and throughput.

Product Protection and Stability

Stretch wrappers provide unparalleled product protection by securely binding palletized loads with stretch film. This safeguards goods against moisture, dust, and debris during transit and storage, ensuring product integrity and customer satisfaction.

Customization and Adaptability

Stretch wrappers offer unparalleled customization and adaptability to diverse packaging requirements. With adjustable parameters such as film tension and wrapping patterns, each load receives precisely the right amount of protection, eliminating inconsistencies often associated with manual wrapping methods.

Cost-Effectiveness

Despite the initial investment, stretch wrappers yield long-term cost savings by optimizing packaging efficiency, reducing material waste, and minimizing product damage. The benefits of enhanced protection and streamlined operations far outweigh the initial expenditure.

Labor Savings and Resource Allocation:

By reducing the dependency on manual labor, stretch wrappers generate significant labor savings. Operators can redirect their time and resources towards more strategic tasks, fostering productivity and innovation within the packaging operation.

Safety and Risk Mitigation:

Stretch wrappers prioritize safety with built-in features such as emergency stops and safety barriers. These measures mitigate the risk of accidents and injuries, ensuring a secure working environment for operators.

Environmental Sustainability:

Stretch wrappers align with sustainability initiatives by optimizing material usage and reducing waste. The eco-friendly approach promotes environmental stewardship and minimizes the carbon footprint of packaging operations.

Conclusion:

In conclusion, stretch wrappers epitomize innovation and efficiency in packaging operations, offering unmatched benefits that redefine industry standards. Embracing stretch wrappers empowers businesses to optimize resources, enhance productivity, and deliver superior quality in an increasingly competitive marketplace. As the cornerstone of modern packaging solutions, stretch wrappers pave the way for innovation and excellence in the packaging industry.

Manual Wrapping vs. Pallet Stretch Wrapper: Navigating the Packaging Paradigm

Introduction

The packaging industry has witnessed a transformative shift with the advent of pallet stretch wrappers. This article aims to navigate the packaging paradigm by comparing manual wrapping methods with the efficiency and advancements offered by pallet stretch wrappers.

Manual Wrapping:

- Labor-Intensive Process:

Manual wrapping involves significant labor input, with operators manually applying stretch film around palletized loads. This process can be time-consuming and may lead to inconsistencies in film application.

- Inconsistent Film Application:

Manual wrapping is susceptible to variations in film tension and application, potentially resulting in uneven coverage. This variability can compromise load stability and product protection.

- Limited Efficiency:

Due to its labor-intensive nature, manual wrapping is generally less efficient, especially in high-volume packaging operations. It may lead to slower throughput and increased labor costs.

- Risk of Operator Fatigue:

Repetitive manual wrapping can lead to operator fatigue and potential injuries, especially when dealing with heavy or cumbersome loads. This poses risks to both personnel and the overall packaging process.

Pallet Stretch Wrapper:

- Automated Efficiency:

Pallet stretch wrapper automate the wrapping process, significantly reducing the time and labor required for packaging. Automated rotation, film dispensing, and cutting enhance overall efficiency.

- Consistent Film Application:

Pallet stretch wrapper provide consistent film application with adjustable parameters for film tension and wrapping patterns. This ensures uniform coverage, load stability, and enhanced product protection.

- Enhanced Throughput:

With their automated capabilities, pallet stretch wrapper contribute to higher throughput and increased operational efficiency. This is particularly advantageous in settings with high-volume packaging requirements.

- Reduced Labor Dependency:

Pallet stretch wrapper reduce dependency on manual labor, minimizing the risk of operator fatigue and injuries. This allows personnel to focus on more strategic tasks within the packaging operation.

- Customization and Adaptability:

Pallet stretch wrapper offer customizable settings to accommodate various load specifications. Operators can adjust parameters such as film tension and wrapping patterns to meet specific packaging requirements.

Conclusion

While manual wrapping methods have been traditionally employed, the efficiency, consistency, and labor-saving benefits offered by pallet stretch wrappers have redefined the packaging landscape. Businesses seeking to optimize their packaging processes, enhance load stability, and improve overall productivity are increasingly turning to pallet stretch wrapper as the preferred choice in the packaging paradigm. Embracing this automated technology not only streamlines operations but also contributes to a safer and more efficient working environment.

Mastering the Art of Pallet Stretch Wrapping: A Comprehensive Guide

Introduction

Pallet stretch wrapping is a fundamental process in modern packaging operations, ensuring load stability, product protection, and supply chain efficiency. This comprehensive guide provides detailed instructions and best practices for mastering the art of pallet stretch wrapping.

- Preparing the Pallet:

- Ensure the pallet is stable and securely loaded with the desired goods.

- Verify that the load is evenly distributed and properly stacked to prevent shifting during wrapping.

- Setting Up the Stretch Wrapper:

- Position the stretch wrapper in a clear and accessible area, ensuring adequate space for loading and unloading pallets.

- Check the machine's settings and adjust parameters such as film tension, wrapping speed, and pre-stretch level as needed for the specific load.

- Loading the Pallet onto the Wrapper:

- Use a forklift or pallet jack to carefully place the loaded pallet onto the turntable or platform of the stretch wrapper.

- Ensure the pallet is centered and aligned with the wrapping zone to facilitate even distribution of the stretch film.

- Initiating the Wrapping Process:

- Start the stretch wrapper according to the selected mode (manual, semi-automatic, or automatic) using the control panel or interface.

- Monitor the wrapping process closely to ensure proper alignment and tension of the stretch film.

- Adjusting Film Application:

- Monitor the film application during the wrapping process and make adjustments to the tension or speed if necessary.

- Ensure that the stretch film covers the entire palletized load evenly, including the top, bottom, and sides.

- Securing the Film:

- Once the wrapping process is complete, use the built-in cutter or clamp to secure the end of the stretch film to the pallet.

- Ensure that the film tail is firmly attached to prevent unraveling during transit or storage.

- Unloading the Wrapped Pallet:

- After wrapping, stop the stretch wrapper and carefully remove the wrapped pallet from the turntable or platform.

- Use the forklift or pallet jack to transport the wrapped pallet to its designated storage or shipping area.

- Maintenance and Safety:

- Conduct regular maintenance checks on the stretch wrapper to ensure optimal performance and longevity.

- Follow safety protocols and guidelines to prevent accidents and injuries during the wrapping process.

Conclusion

Mastering the art of pallet stretch wrapping requires attention to detail, proper technique, and adherence to safety protocols. By following the steps outlined in this guide, businesses can achieve optimal load stability, product protection, and operational efficiency in their packaging operations. Pallet stretch wrapping serves as a critical component of modern supply chain logistics, ensuring that goods are securely packaged and ready for distribution to customers worldwide.

Revolutionizing Packaging Efficiency: The Integration of Scale Wrappers

Introduction

In the dynamic landscape of packaging and logistics, scale wrappers represent a significant advancement, combining precision weighing capabilities with automated wrapping functions. This article explores the transformative impact of scale wrappers in enhancing packaging efficiency and accuracy.

- Streamlined Packaging Process

Scale wrappers streamline the packaging process by integrating weighing and wrapping functions into a single operation. This eliminates the need for separate equipment and reduces processing time, enhancing overall workflow efficiency.

- Precise Weight Measurement

With integrated weighing systems, scale wrappers provide precise weight measurements of palletized loads. This ensures compliance with shipping regulations and facilitates accurate load documentation, reducing the risk of fines and discrepancies.

- Automated Wrapping

Scale wrappers automate the wrapping process, optimizing film usage and ensuring consistent wrapping patterns. Automated rotation, film dispensing, and cutting functionalities contribute to higher throughput and enhanced operational efficiency.

- Customizable Settings

Scale wrappers offer customizable settings for weight thresholds, units of measurement, and wrapping parameters. Operators can adjust settings to accommodate various load specifications and packaging requirements, ensuring flexibility and adaptability.

- Labor Savings

By reducing dependency on manual labor, scale wrappers generate significant labor savings. Operators can allocate their time and resources to more strategic tasks, improving productivity and operational efficiency.

- Data Management and Analysis

Some scale wrappers are equipped with data logging capabilities, allowing for the recording and storage of weight measurements and packaging parameters. This data can be analyzed to optimize packaging processes, improve quality control, and enhance inventory management practices.

- Enhanced Load Stability

Precise weight measurements provided by scale wrappers contribute to enhanced load stability and product protection. This minimizes the risk of load shifting during transit and storage, reducing the likelihood of product damage and waste.

- Environmental Sustainability

Scale wrappers promote environmental sustainability by optimizing material usage and reducing waste. The efficient use of stretch film minimizes the environmental footprint of packaging operations, aligning with corporate sustainability initiatives.

Conclusion

In conclusion, scale wrappers represent a paradigm shift in packaging technology, offering unparalleled efficiency, accuracy, and versatility. By integrating weighing and wrapping functions, scale wrappers streamline packaging operations, reduce labor dependency, and enhance load stability. Businesses looking to optimize their packaging processes and maintain regulatory compliance should consider incorporating scale wrappers into their operations. As the cornerstone of modern packaging solutions, scale wrappers pave the way for innovation and excellence in the packaging industry.